HRC60 2 Flutes Tungsten Carbide Square End Mills Cutting Tools Blue Nano Coating

Coating

Coating |

Color |

Coating Temperature |

Thickness (um) |

HV |

Application Temperature |

Friction coefficient |

TiAlN |

Purple-Gray |

<600°C |

3-5 |

3300 |

800 °C |

0.3 |

| AlTiN |

Black |

<600 °C |

3-5 |

3500 |

900 °C |

0.3 |

| TiSiN |

Copper |

<600 °C |

3-5 |

3500 |

1500 °C |

0.4 |

| NaNo |

Blue |

<600 °C |

3-5 |

3800 |

1200 °C |

0.4 |

| CrN |

Silver Gray |

<480 °C |

2-2.5 |

2500 |

700 °C |

0.3 |

GOOD WEA R RESISTANCE, LONG WORKING LIFE, NANO COATING

Made with Anka machine tools and German technology, it can perform finishing and semi-finishing on heat-treated materials below 55 degrees, enhance tool life, reduce the number of roundabouts, and provide machine tool operation.

- BIG DIAMETER DESIGN , SHARP CHIP REMOVAL

The unique helix angle is ground by first-class precision machine tools. The large core diameter design enhances rigidity and shock resistance .The large chip removal space is not easy to accumulate chips, and is not easy to break. It is sharp and wear-resistant, cutting smoothly, and improving milling efficiency.

Sharp Cutting Edge

Improve the effective

Hard and long working life

- WITH PASSIVATION TREATMENT, DURABLE AND ANTI-CORROSION

Imported passivation equipment, finely densified sand, increases the corrosion resistance and wear resistance of the end mill. Good grinding makes the cutting edge without chips. It can Extended the working life.

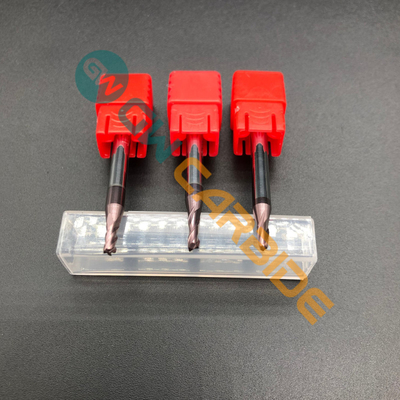

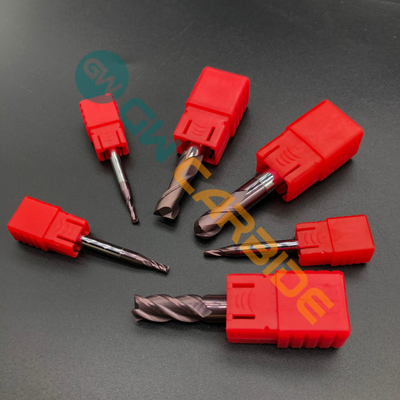

HRC60 2 Flutes Flat Solid carbide end mils

Materials:Solid Carbide

Brand: GREWIN

Coating: Copper coating

Flute:2 flutes

Hardness: HRC60

Spiral Angle: 35

Materials to be cut: 45# steel, cast lron, tool steel and mould steel within HRC60

Machine to be used: CNC machining centers, engraving machines and other high-speed CNC milling machines

A SOLID CARBIDE END MILL WHO UNDERSTAND WHAT YOU WANT

Real end mill photo, you will get what you read from the picture

WARMLY TIPS

01Properly reducing the cutting speed and feed rate can prolong the trial life of the milling cutter.

02When working, it is necessary to add cutting fluid to protect the cutting edge, which makes the cutting smoother.

03When there is an oxide film or other hardened layer remaining on the surface of the work-piece, it can be removed by reversible milling.

INSTRUCTIONS FOR USE

What buyers need to know about end mill selection and operating instructions

01.Before using the tool, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

02.The shorter the length of the end mill sticking out of the chuck, the better.If the end mill sticks out for a long time, it is necessary to reduce the rotational speed, feed rate or cutting amount.

03.During cutting, if abnormal vibration or sound occurs, please reduce the cutting speed and the cutting feed rate until the situation improves.

04.The steel cooling is preferably spray and air jet, which can effectively improve the use effect of the milling cutter.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!